Occupational Safety and Health

- Policy & Management Approach

- Hazard Identification & Risk Assessment

- Building a Resilient Safety Culture

- Workplace Safety & Health Training

- Employee Communication

- Occupational Health Services & Promotion

- Occupational Incidents & Injuries

Occupational Safety & Health Management System: Policy and Measures

Policy & Commitment

Everlight Chemical implements the following measures:

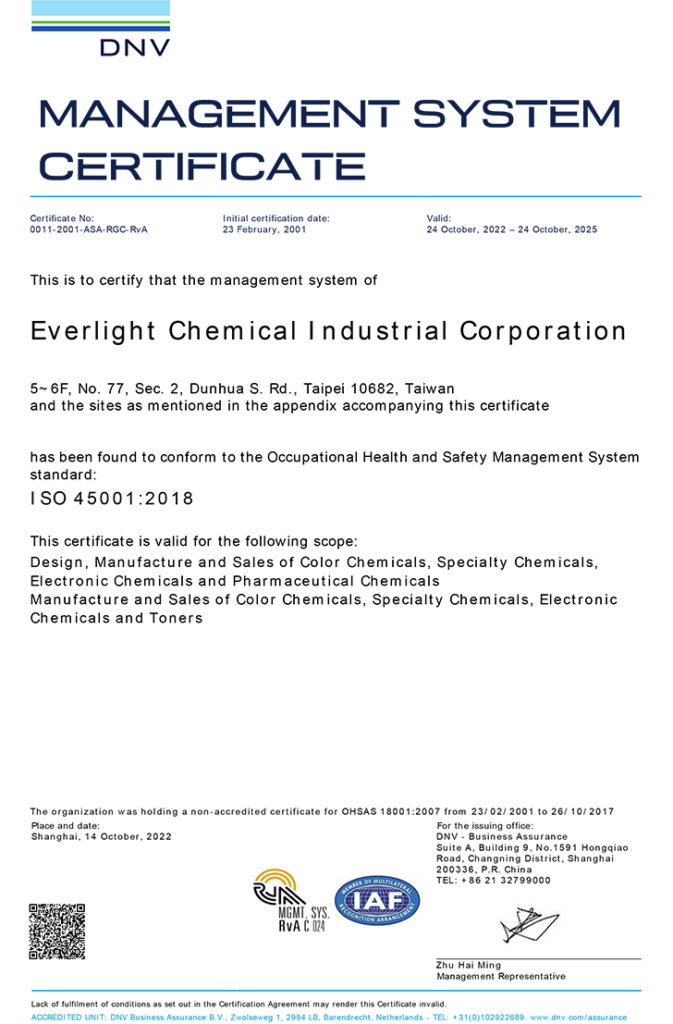

- Implement an ISO 45001 Occupational Safety and Health Management System

- Provide safe and healthy working conditions

- Comply with safety and health regulations and other requirements

- Eliminate hazards and reduce occupational safety and health risks

- Facilitate safety and health consultation with workers and encourage participation

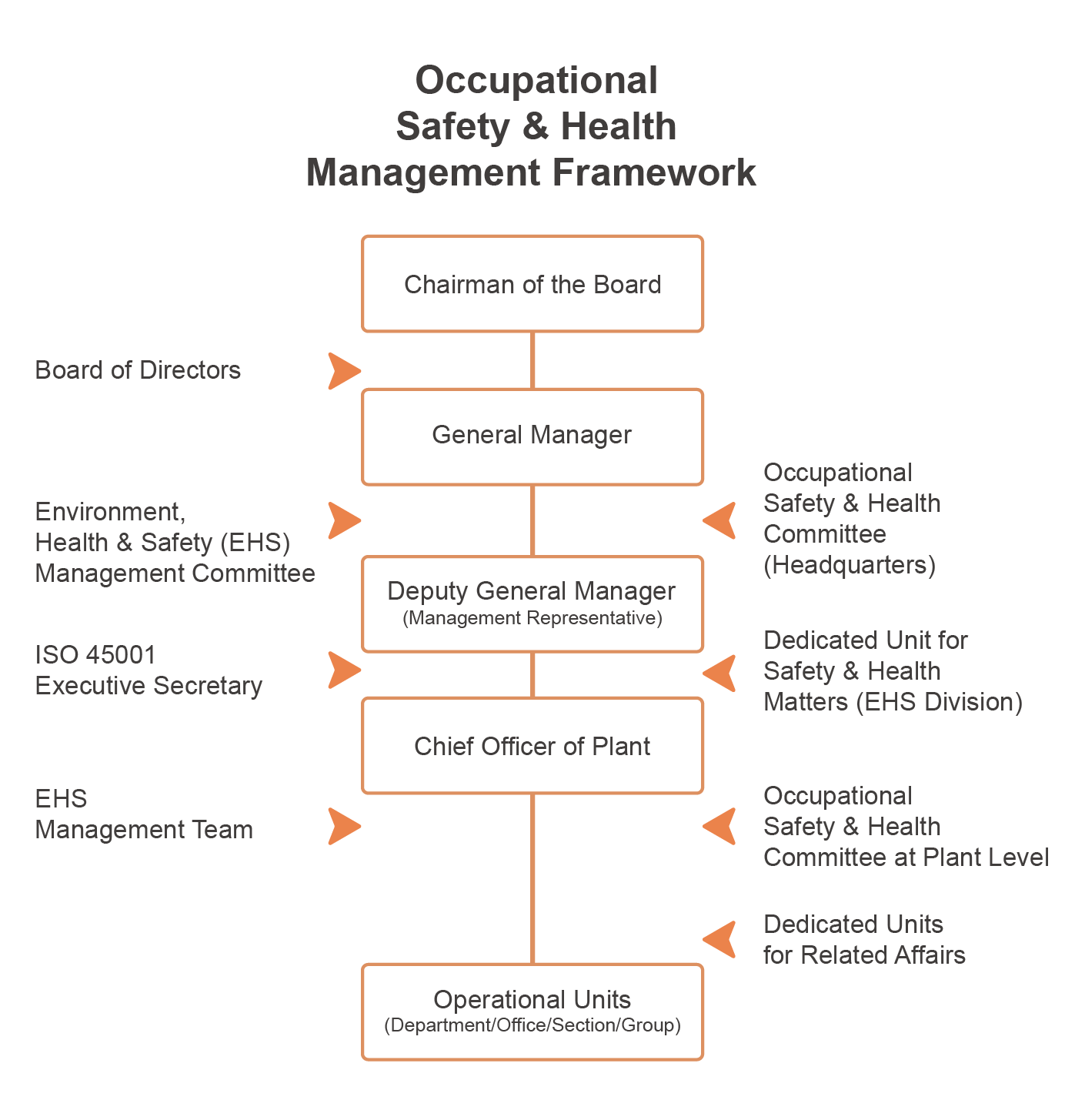

Governance Body

審議委員會名稱

場址:營運總部

場址:永光一二三廠

場址:永光四廠

場址:全通科技一二三廠

場址:蘇州永光

First-level Occupational Safety & Health Management Unit

Management Approach

KPI #2: Progress on Establishing a Process Safety Management (PSM) System

Evaluation Mechanism

(2) ESG committee meetings (twice every year)

(3) Plant policy reviews (quarterly)

(4) Internal audits on our safety and health management system (annual) based on the Company’s internal auditing plan and conducted by an audit team composed of trained and qualified personnel. The dates of internal audits in 2022 are as follows:

Location | ECIC HQ | ECIC Plant I | ECIC Plant II | ECIC Plant III | ECIC Plant IV | TTI Plant I-III | Everlight Suzhou |

Date of Audit | 2022/4/7 | 2022/3/15 | 2022/3/17 | 2022/4/8 | 2022/3/21 | 2022/5/11-5/18 | 2022/3/29-4/1 |

Grievance Mechanism

We have established the following procedures and mechanisms to ensure remediation of negative impacts and to collect feedback.

- Publicly post information about our complaint mechanism in accordance with Article 32 of the Labor Inspection Act (applicable to locations in Taiwan)

- Complaint mechanism for illegal workplace abuse: One complaint was filed in 2022. The complaint was promptly and properly resolved according to relevant internal policies.

- Complaint mechanism for violation of employee rights

- Complaint mechanism for workplace sexual harassment

Occupational Safety & Health (OSH) Management & Accomplishments

(ECIC Plant I-IV, Trend Tone Imaging, Everlight Suzhou)

We also implement the 5S routine and “Know Your Hazard” pointing & calling safety methods in our daily operations.

106 safety and health proposals were raised under our proposal system (17% of all proposals).

(2) We have completed three explosion hazard training sessions.

(2) The system enables digital regulatory compliance management for chemical raw materials.

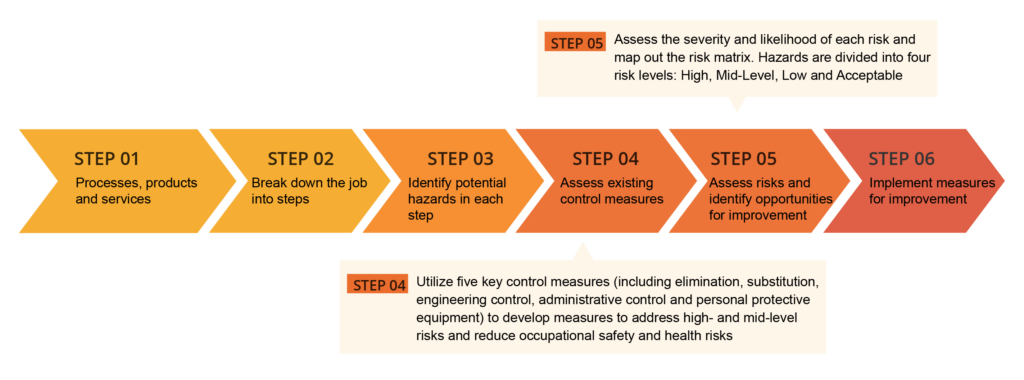

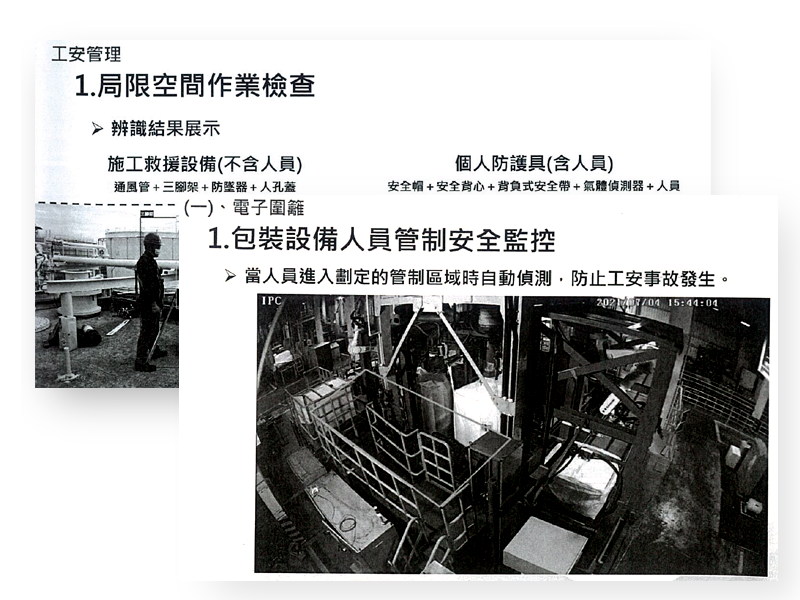

Hazard Identification and Risk Assessment

Occupational Safety & Health Management System and Indicators

Type | Locations with ISO 45001 Certificate | Locations with ISO 45001 Certificate | Total Headcount | |||||||

Headcount | ECIC HQ | ECIC Plant I-IV | TTI Plant I-III | Everlight Suzhou | Subtotal | Business Office (Taiwan) | Administrative Subsidiaries (China) | Administrative Subsidiaries (US, Netherlands, Turkey) | Subtotal | |

Employees | 160 | 1,130 | 204 | 172 | 1,662 | 12 | 87 | 53 | 152 | 1,814 |

Non-Employees | 0 | 13 | 2 | 0 | 15 | 0 | 0 | 0 | 0 | 15 |

Medium and High-Level Risks Identified | Implementation Results of Health & Safety Objectives/Targets/Projects | ||||

Type | Number of Risks | Hazard Type | Item | Target | Actual |

High Risk | 0 | None | Objectives | 17 | 16 |

Medium Risk | 38 | Exposure to hazardous substance/condition, fire and explosion, falling object, collision, electric shock, collapse, caught-in hazard, oxygen deficiency, fall or roll hazard, drowning | Targets | 23 | 22 |

Implementing Robust Safety & Health Management to Build a Resilient Safety Culture

Chemical Safety Management

No Data Found

Machinery Management

Procurement Management

Contractor Management

Change Management

Permit Management

No Data Found

Non-conformance Management

Workplace Safety & Health Training

394

175

2,918

4,075

2,595

18,137

Employee Communication on Occupational Safety & Health

Location | Number of Meetings | Number of Committee Members | Number & Share of Worker Representatives | Note | |

ECIC HQ (Taipei) | 4 | 13 | 5 | 38% | Matters reviewed by the occupational safety and health committees:

|

ECIC Plant I (Dayuan) | 4 | 25 | 14 | 56% | |

ECIC Plant II (Guanyin) | 4 | 30 | 11 | 36% | |

ECIC Plant III (Guanyin) | 4 | 15 | 5 | 33% | |

TTI Plant I-III (Hsinchu) | 4 | 14 | 7 | 50% | |

Everlight Suzhou (Suzhou) | 8 | 20 | 6 | 30% | Local regulations do not stipulate the share of worker representatives required on a committee. Regulations related to work safety standardization only require the safety and health committee to hold at least one meeting each quarter and pass on related information to employees. |

Other Procedures for Engagement, Consultation, Communication and External Communication:

External communication is conducted through the company website; advertisement; participation in industry associations, social welfare activities, local events, information sessions for related stakeholders; in-person visits; and internal publications.

Implementing Health Services & Promotion

Subject | New Employees | All Employees (Annual) | Health Examination for Senior Employees | ||

Type | Regular Physical Checkup | Special Physical Checkup | Regular Health Examination | Special Health Examination | |

No. of Recipients | 217 | 98 | 1,368 | 412 | 93 |

Subject | ECIC HQ | ECIC Plant I | ECIC Plant II | ECIC Plant III | ECIC Plant IV | TTI Plant I-III |

On-Site Medical Services by Doctors | 4 | 6 | 12 | 6 | 1 | 4 |

On-Site Medical Services by Nurses | 48 | 72 | Full-time | 72 | 12 | 48 |

Employees who Attended Health Education Activities | 33 | 98 | 90 | 34 | 21 | 33 |

Employees who Scheduled Consultation Session for Health Guidance | 122 | 10 | 72 | 90 | 21 | 122 |

Maternal Health Protection | Reports of Abnormal Workload | Number of Ergonomics Improvements | Number of Illegal Workplace Abuse Complaints | |

Pregnant | 1 Year after Childbirth | |||

11 | 7 | 5 | 3 | 1 (Resolved in accordance with relevant internal policies) |

Occupational Incidents and Injuries

Location Incident Type | Everlight Chemical | Trend Tone Imaging | Everlight Suzhou |

Death or Severe Occupational Injury | General Manager | General Manager | Chief Officer of Plant |

Recordable Occupational Injury | Chief Officer of Plant | General Manager | Chief Officer of Plant |

There had been 0 transport incidents for the past four years. (Note: only inclusive of transportation where ownership of transported goods belonged to Everlight Chemical Group)

In 2022, there were a total of 46 close calls and safety incidents combined. Further breakdown is as follows:

No Data Found

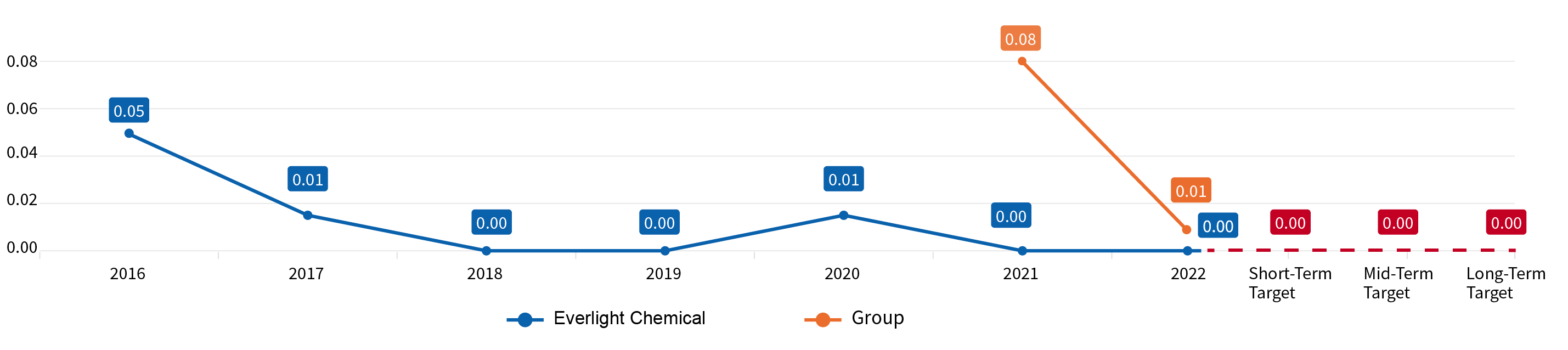

Item | Death | Permanent Total Disability | Permanent Partial Disability | Temporary Total Disability | Absenteeism Rate (AR) | Fatality Rate for Occupational Injuries | Occupational Disease Rate (ODR) | Injury Rate (IR) | Lost Day Rate (LDR) | Process Safety Total Incident Rate (PSTIR) | Process Safety Event Severity Rate (PSESR) | |||||

Incidents | Days | Incidents | Days | Incidents | Days | Incidents | Days | Severe | Recordable | |||||||

2021 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 23 | 1.07 | 0 | 0 | 0 | 5.04 | 6.44 | 0.22 | None |

2022 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 4 | 5.21 | 0 | 0 | 0 | 4.27 | 1.14 | 0.28 | 0.91 |

Item | Death | Permanent Total Disability | Permanent Partial Disability | Temporary Total Disability | Absenteeism Rate (AR) | Fatality Rate for Occupational Injuries | Occupational Disease Rate (ODR) | Injury Rate (IR) | Lost Day Rate (LDR) | Process Safety Total Incident Rate (PSTIR) | Process Safety Event Severity Rate (PSESR) | |||||

Incidents | Days | Incidents | Days | Incidents | Days | Incidents | Days | Severe | Recordable | |||||||

2021 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | None |

2022 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Note:

(1) The fatality rate for occupational injuries, occupational disease rate (ODR), severe/recordable injury rate (IR) and lost day rate (LDR) are calculated per million hours worked and rounded down to the third decimal place.

(2) The process safety total incident rate (PSTIR) and process safety event severity rate (PSESR) are calculated per 200,000 hours worked and rounded down to the third decimal place.

(3) Non-employees refer to workers providing on-site services at Everlight Chemical’s operational locations during the year whose employers were not Everlight Chemical.

(4) Calculation does not include traffic accidents during commute to and from work.