Circular Economy

- Circular Economy Strategy

- Framework & Process

- Inner Loop & Outer Loop

- Applications & Accomplishments

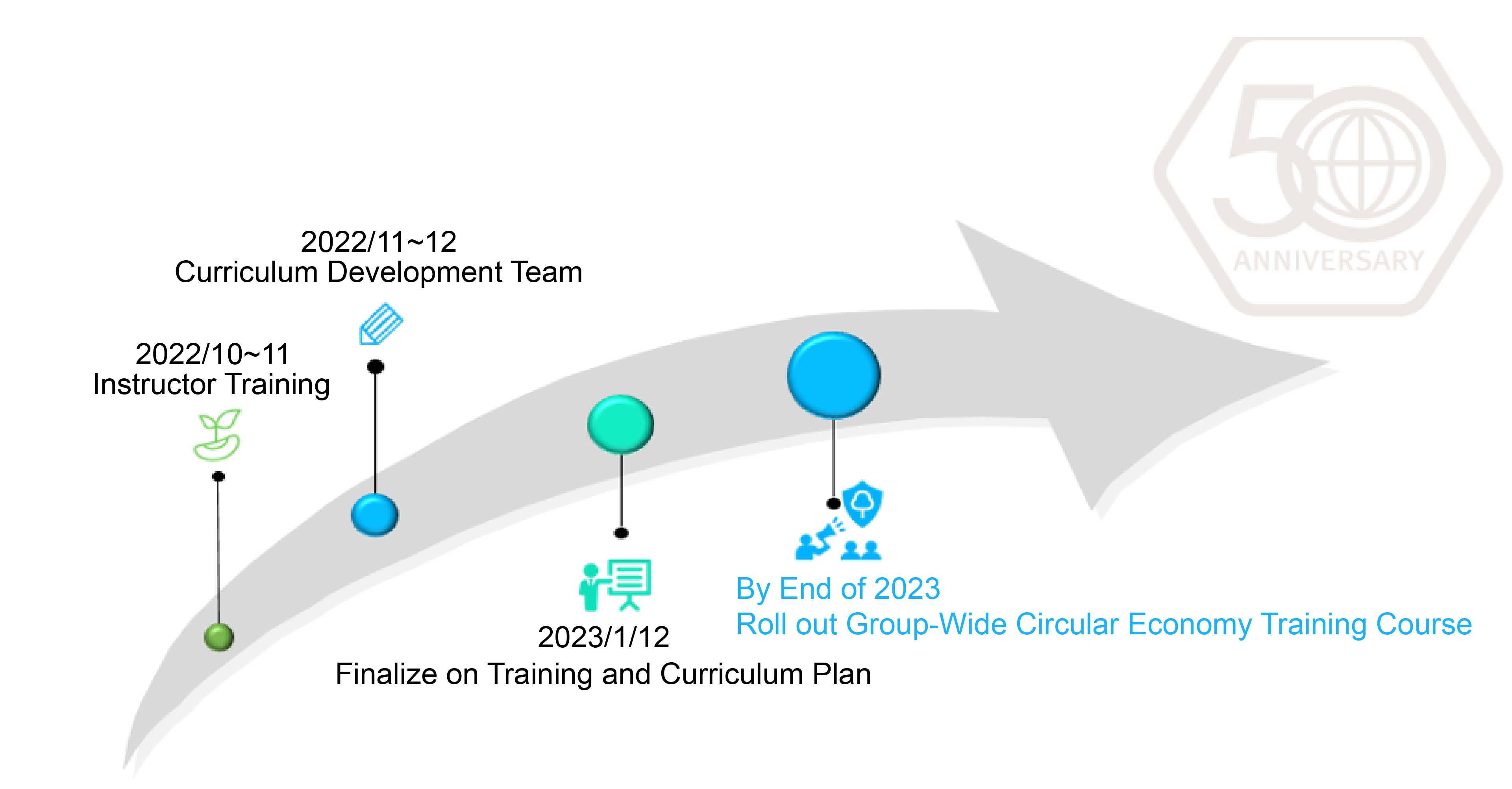

- Sustainability & Circular Economy Training Project

Everlight Chemical’s Brand Commitment:

Better Chemistry Better Life. Everlight Chemical is committed to the pursuit of improvement and innovation. Harnessing a deep passion for research and connecting the best talent and ideas, we continue to create new possibilities. With unmatched expertise in the chemical industry, we support and contribute to the success of our customers. Our work helps build a better community and ensure a sustainable future. We believe that the innovative application of chemistry can help make the world a better place.

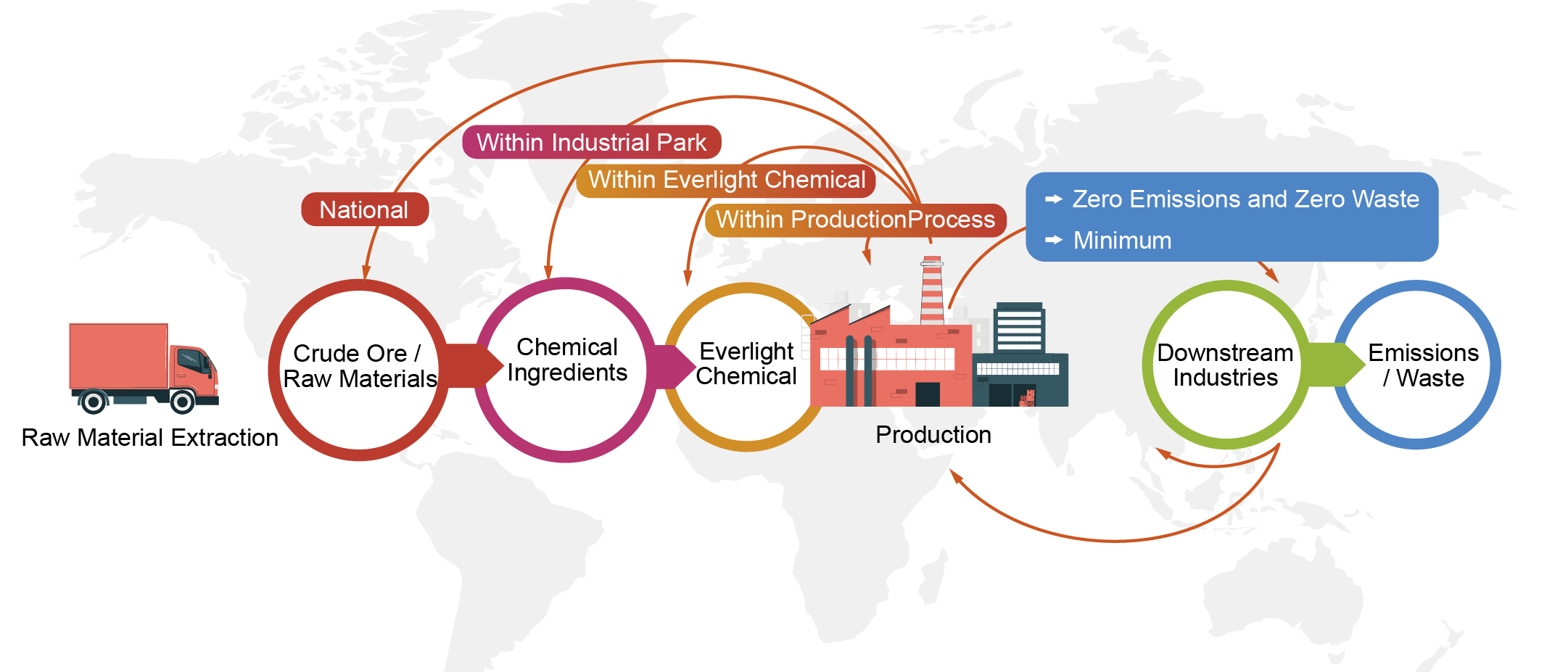

To ensure a sustainable environment for future generations, the transition from linear to a circular economy is crucial. As a professional chemical manufacturer, we aspire to serve as a catalyst for the transformation to a circular economy within the chemical supply chain, creating a better life for all.

Our Purpose

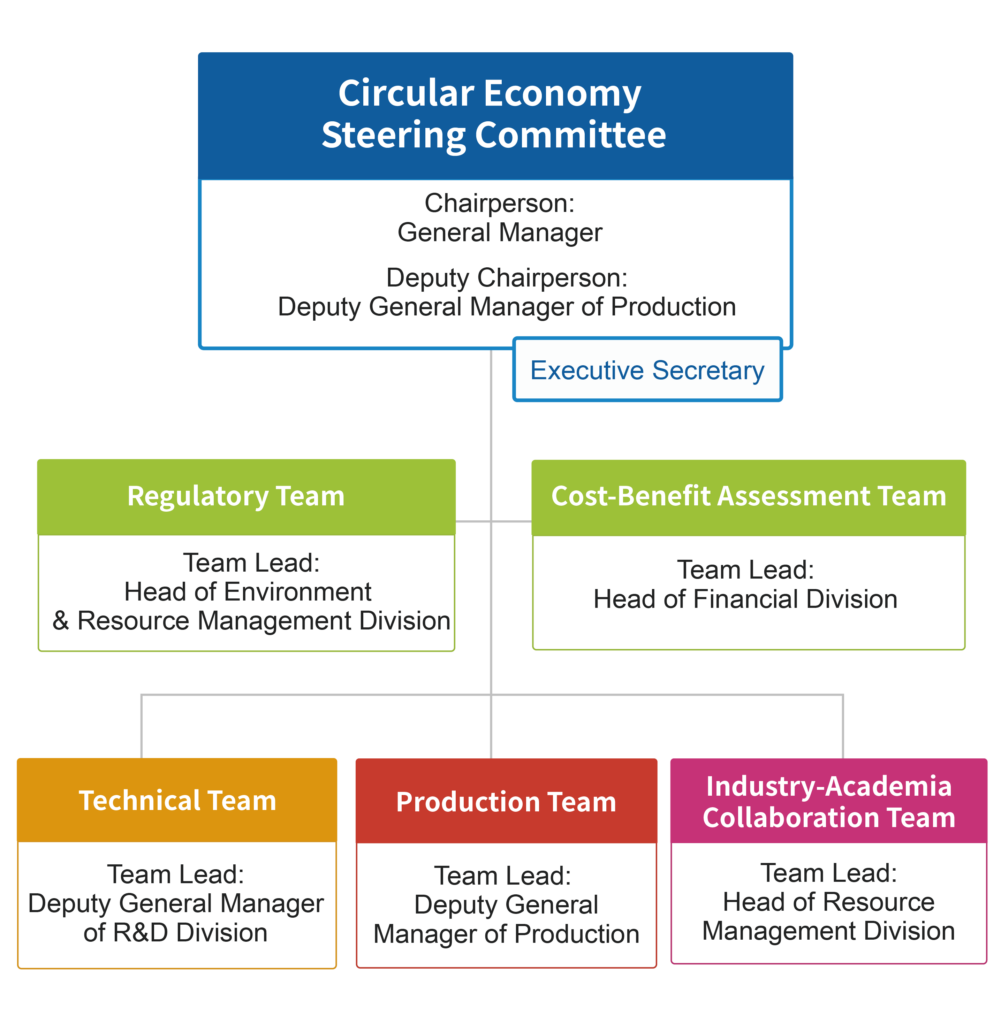

- The Company’s General Manager serves as the chairperson of the committee and is responsible for promoting and overseeing progress on circular economy goals. The Deputy General Manager of Production is the deputy chairperson of the committee and is responsible for assisting the chairperson’s work in facilitating circular economy practices.

- Committee members also include team leads of the teams under the committee.

- The committee has also appointed an Executive Secretary, who is responsible for consolidating and announcing information on the committee’s work and decisions.

- Procedures:

The committee holds regular meetings in the second and fourth quarters of each year to report on and review implementation results, adjust goals related to the circular economy, and report upwards.

The committee holds regular meetings in the second and fourth quarters of each year to report on and review the implementation results, as well as to adjust goals related to the circular economy as needed. Committee meetings are chaired by the Chairperson, or by the Deputy Chairperson in the Chairperson’s absence. Each team under the committee is responsible for overseeing the reports and implementation results by related departments. The Executive Secretary is responsible for sending meeting notifications, preparing meeting minutes, and tracking the performance of each team.

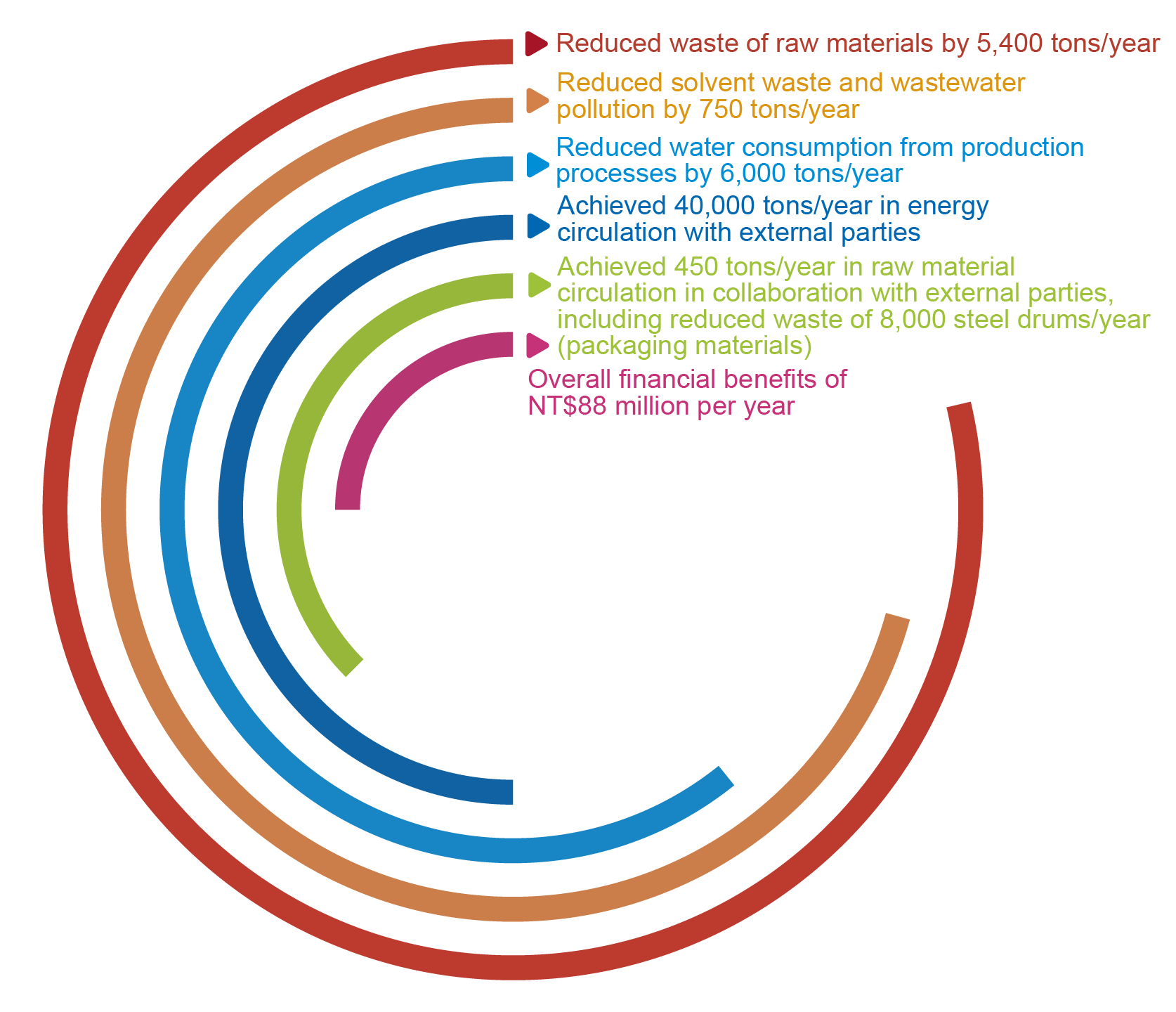

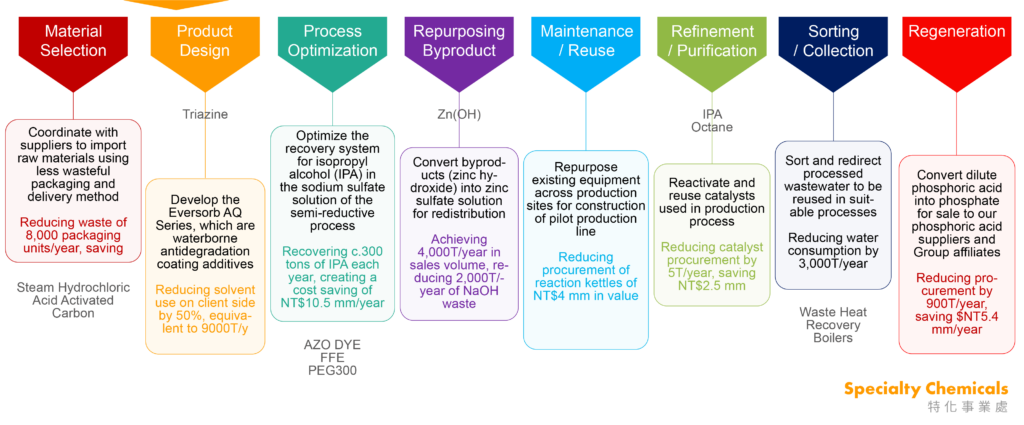

- Within the company, we process used materials through various methods (such as filtration, distillation

- As an example, in 2022, we applied membrane separation technology to purify PEG300 used in our manufacturing process for reuse in our production process. The approach has helped us recycle around 250 tons of PEG300 annually, contributing to a cost saving of NT$8 million per year.

- We collaborate with our upstream suppliers and downstream clients to reuse packaging materials or revitalize used raw materials, reducing expenses on packaging materials and waste generated in production processes.

- For example, in terms of raw material packaging, we worked with our suppliers to replace steel drums with tanker trucks to transport imported raw materials and deliver them in batches based on our production needs. This led to a waste reduction of 8,000 steel drums (and a cost saving of NT$7.5 million) each year and also helped optimize storage space at our production facilities.

The Circular Economy Model We Aspire to Implement

- Adjustment of growth model

- Awareness of limited resources

- Zero-waste production process

- Collaboration with other businesses

With a focus on the circular economy, our plants actively adopt green chemistry practices.

Building a Circular Supply Chain and Implementing Green Chemistry