Environmental Sustainability Management

Material Topic #3

Impact Assessment

Type: Includes both positive and negative impacts

Description: Positive impact: We actively promote and implement green chemistry and circular economy practices. We also implement the ISO 14001 Environmental Management System, supporting net-zero emissions and other environmental management initiatives that contribute to positive environmental impact.Negative impact: Our production processes inevitably consume energy and resources and generate air pollutants, wastewater and waste that require proper processing prior to discharge. We implement a wide range of pollution prevention and waste management measures to effectively manage and reduce these negative impacts.

Description: Positive impact: We actively promote and implement green chemistry and circular economy practices. We also implement the ISO 14001 Environmental Management System, supporting net-zero emissions and other environmental management initiatives that contribute to positive environmental impact.Negative impact: Our production processes inevitably consume energy and resources and generate air pollutants, wastewater and waste that require proper processing prior to discharge. We implement a wide range of pollution prevention and waste management measures to effectively manage and reduce these negative impacts.

Environmental protection is a top priority for Everlight Chemical. Relevant material topics include regulatory compliance and pollution prevention. Our efforts have been reflected in our environmental management costs as well as performance across various indicators. Our management approach for this material topic is as follows:

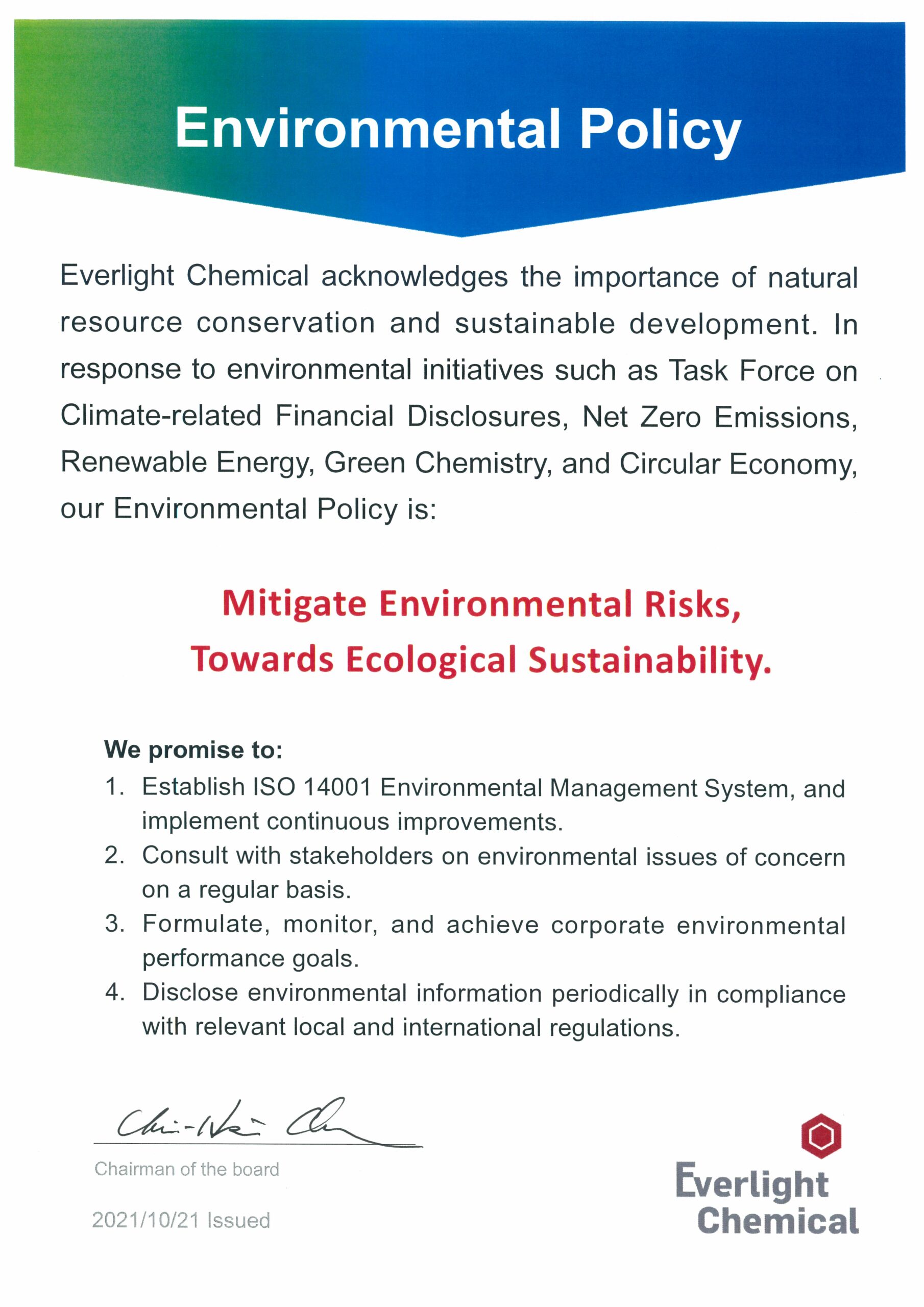

Management Policy & Commitment

With “Mitigate Environmental Risks, Towards Ecological Sustainability” as the guiding principle of our Environmental Policy, we implement rigorous management measures and are committed to the following:

- Establish ISO 14001 Environmental Management System, and implement continuous improvements.

- Consult with stakeholders on environmental issues of concern on a regular basis.

- Formulate, monitor, and achieve corporate environmental performance goals.

- Disclose environmental information periodically in compliance with relevant local and international regulations.

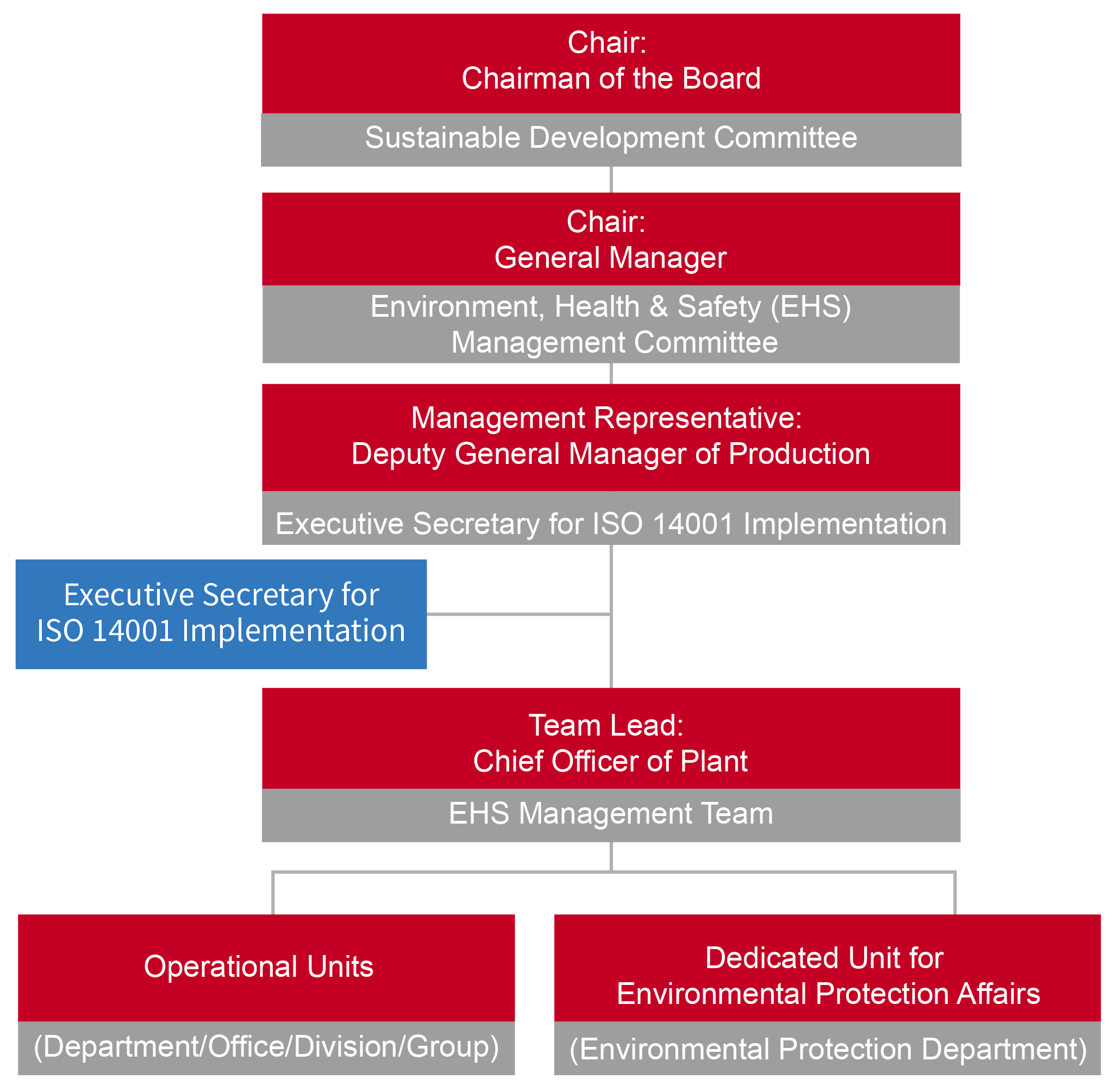

Environmental Management Framework & Responsibilities

To strengthen the Company’s environmental management performance, the Sustainable Development (ESG) Committee is led by the Company’s chairman and oversees progress on related performance indicators.

Organizational Structure &

Responsibilities

- The chairman of the board chairs the ESG Committee.

- The General Manager chairs the Environment, Health & Safety (EHS) Management Committee and oversees the Company’s overall performance on environmental sustainability.

- The Deputy General Manager of Production is the management representative for the implementation of ISO 14001 and oversees the effectiveness of the environmental management system at plants.

- At the plant level, an EHS management team (led by chief officers of each plant) and dedicated environmental protection unit/personnel are in place to oversee and manage environmental risks related to production and measures related to environmental protection at the plant.

Frequency of Environmental Management Meetings

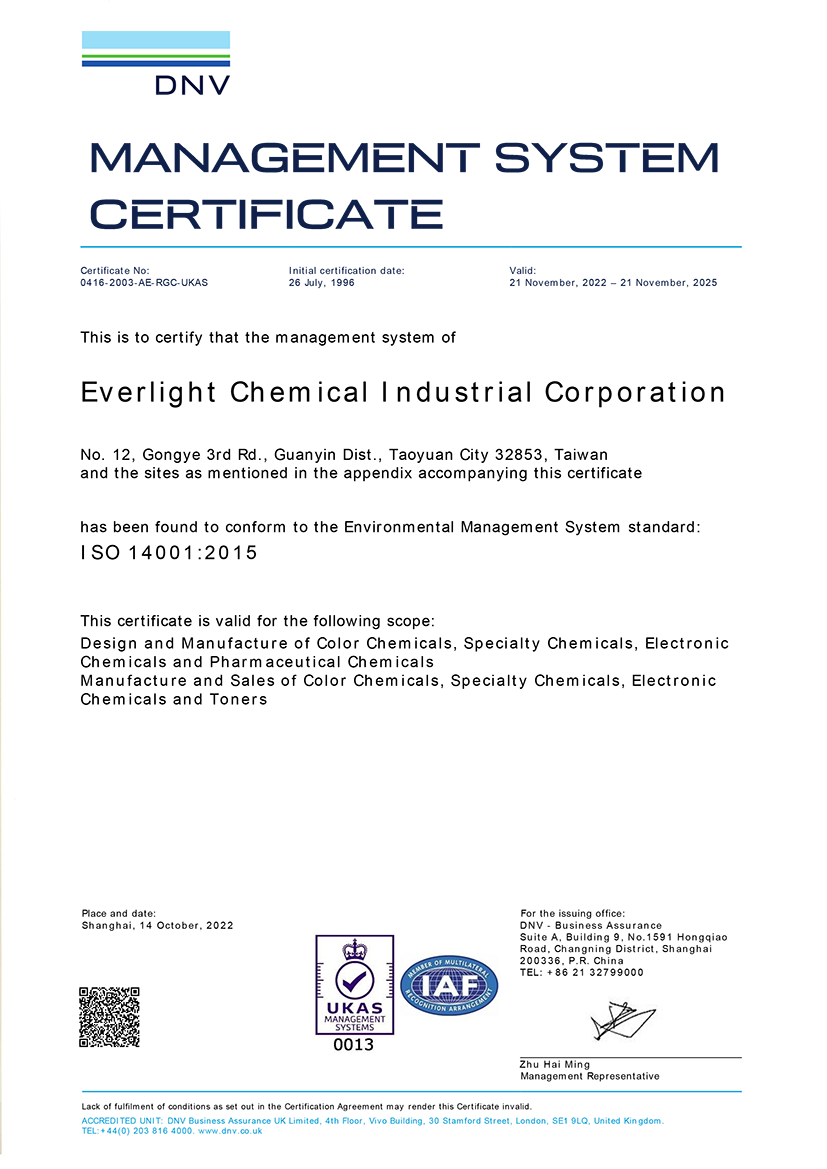

To align our EHS policy and practices with international standards, we implement ISO 14001 in our environmental management system. ECIC Plant I-IV, Trend Tone Imaging and Everlight Suzhou have all obtained ISO 14001 certification.

Impact Assessment

Type: Includes both positive and negative impacts

Positive Impact:We actively promote and implement green chemistry and circular economy practices. We also implement the ISO 14001 Environmental Management System, supporting net-zero emissions and other environmental management initiatives that contribute to positive environmental impact.

Negative Impact: Our production processes inevitably consume energy and resources and generate air pollutants, wastewater and waste that require proper processing prior to discharge. We implement a wide range of pollution prevention and waste management measures to effectively manage and reduce these negative impacts.

Positive Impact:We actively promote and implement green chemistry and circular economy practices. We also implement the ISO 14001 Environmental Management System, supporting net-zero emissions and other environmental management initiatives that contribute to positive environmental impact.

Negative Impact: Our production processes inevitably consume energy and resources and generate air pollutants, wastewater and waste that require proper processing prior to discharge. We implement a wide range of pollution prevention and waste management measures to effectively manage and reduce these negative impacts.

Management Approach

Prevention/Mitigation:

1. Formulate environmental policy and goals: We have established clear environmental policy and goals to guide our business activities and promote sustainability.

2. Develop environmental management process: We have established processes to ensure our operations comply with related environmental regulations and standards.

2. Develop environmental management process: We have established processes to ensure our operations comply with related environmental regulations and standards.

Remediation:

1. Enhanced employee training: Everlight Chemical provides comprehensive environmental training and resources for employees. This ensures that employees are well-informed about the Company’s environmental policy and equipped to perform their roles responsibly.

2. Monitoring and reporting: We have a monitoring and reporting mechanism in place to track the environmental impacts of our activities and promptly report related issues.

2. Monitoring and reporting: We have a monitoring and reporting mechanism in place to track the environmental impacts of our activities and promptly report related issues.

Impact Management:

We regularly review our management systems and processes to make sure that they align with the latest environmental regulations and standards and make adjustments based on performance assessments.

Metrics and Targets

We use six performance indicators to track progress. These indicators are the water recovery rate (R2) (%), emissions reduction rate per unit of production (%), waste recycling and reuse rate (%), proper disposal rate of hazardous industrial waste (%), recycling rate of hazardous industrial waste (%) and atom efficiency (%).

How We Track the Effectiveness of Actions Taken

- Processes: We implement the PDCA (Plan-Do-Check-Act) cycle and regularly hold environment, health and safety (EHS) performance review meetings to evaluate and improve performance on different environmental goals.

- Tracking Effectiveness of Actions: We evaluate effectiveness by reviewing performance on the goals and targets we set each year.

- Lessons Learned: We have achieved great accomplishments in implementing green chemistry and circular economy practices. We will continue to pursue environmental sustainability through measures like enhancing atom efficiency and production process improvement, aiming to reduce the carbon footprint of our products. We also actively participate in community engagement and educational programs to promote environmental awareness.

Stakeholder Engagement

Relevant Stakeholders include shareholders/Investors, customers/brand owners, suppliers/contractors, nearby communities and government agencies. We communicate with shareholders through various channels on both a regular and ad hoc-basis.

Environmental Management System & Processes

To align our EHS policy and practices with international standards, we implement ISO 14001 in our environmental management system. ECIC Plant I-IV, Trend Tone Imaging and Everlight Suzhou have all obtained ISO 14001 certification.

We implement the PDCA (Plan-Do-Check-Act) cycle and regularly hold environment, health and safety (EHS) performance review meetings to evaluate and improve performance on different environmental goals. Our environmental management process includes the following steps:

We implement the PDCA (Plan-Do-Check-Act) cycle and regularly hold environment, health and safety (EHS) performance review meetings to evaluate and improve performance on different environmental goals. Our environmental management process includes the following steps:

Operational Reviews:

Management would assess key risks and opportunities based on environmental topics of stakeholders’ concern and formulate environmental management plans.

Management would assess key risks and opportunities based on environmental topics of stakeholders’ concern and formulate environmental management plans.

Environmental Assessment:

Based on the management plans, each plant considers environmental factors specific to their operations and relevant regulatory obligations to identify products, activities, and services that may have material impact on the environment and set environment-related goals/targets accordingly.

Based on the management plans, each plant considers environmental factors specific to their operations and relevant regulatory obligations to identify products, activities, and services that may have material impact on the environment and set environment-related goals/targets accordingly.

Risk & Opportunity Identification:

Relevant risks are identified and analyzed to determine material risks or opportunities.

Relevant risks are identified and analyzed to determine material risks or opportunities.

Planning & Implementation:

Departments or personnel will be assigned to facilitate related action plans; employees receive regular training on skills and awareness of environmental issues; projects are rolled out in accordance with the PDCA cycle and ISO 14001 requirements.

Departments or personnel will be assigned to facilitate related action plans; employees receive regular training on skills and awareness of environmental issues; projects are rolled out in accordance with the PDCA cycle and ISO 14001 requirements.

Regular Audits for Continuous Improvement:

Internal audits and external audits are conducted on an annual basis.

Internal audits and external audits are conducted on an annual basis.

Scope of Environmental Management System Certification

(All locations below have obtained ISO 14001 certification)

Certification Date: 2022/11/21

Valid through:2025/11/21