Quality Management

Material Topic #5

Customer Relationship and Marketing Development

Category: Positive Impact

Description: The products Everlight Chemical produces by implementing green chemistry principles help reduce negative environmental impacts and make positive contributions to the economy. Our high-quality products enable customers and end users to engage in subsequent production activities.

Impact Assessment

Description: The products Everlight Chemical produces by implementing green chemistry principles help reduce negative environmental impacts and make positive contribution to the economy. Our high-quality products enable customers and end users to engage in subsequent production activities.

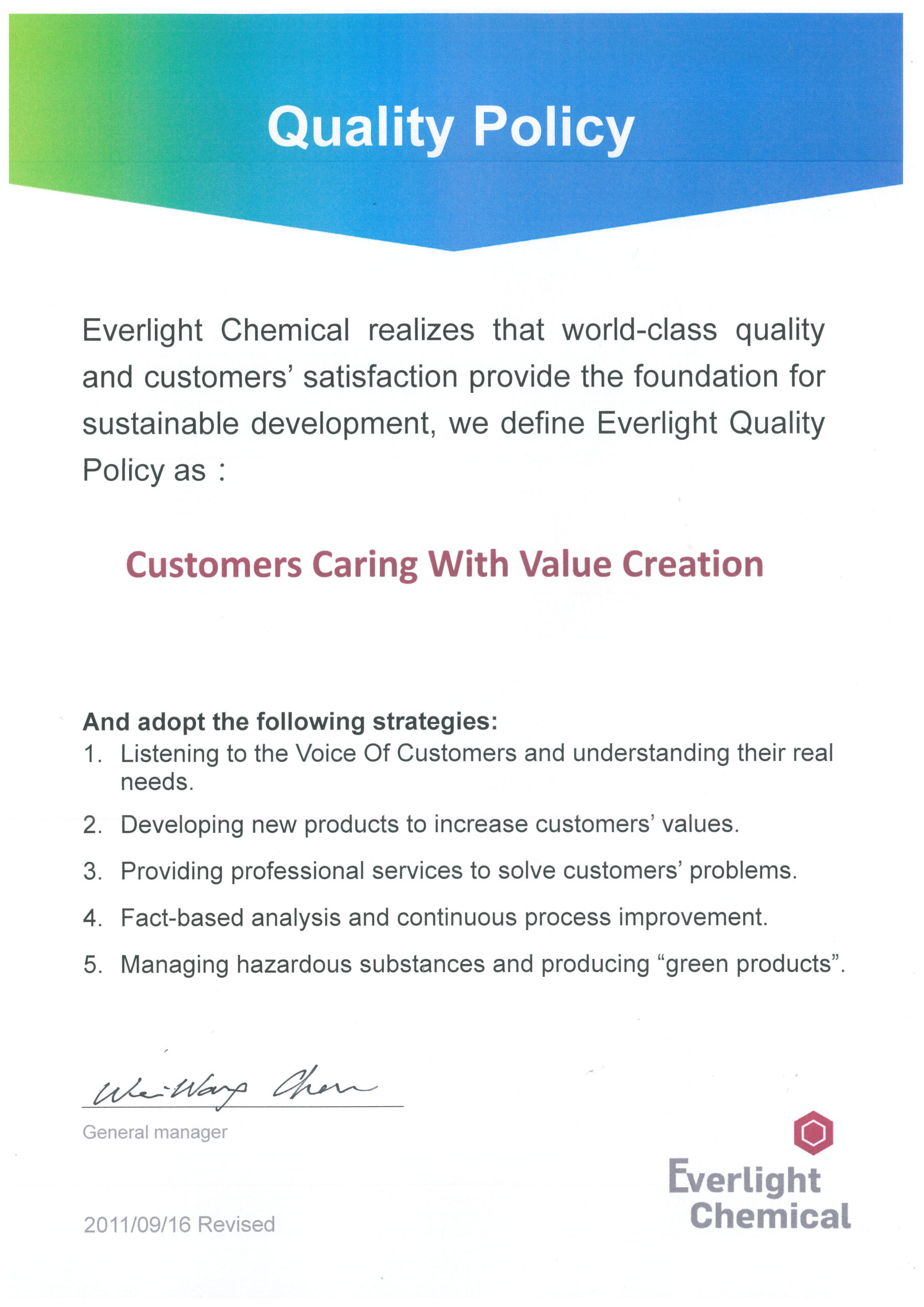

Policy & Commitment

– Implement the ISO 9001 quality management system (adopted since 1994)

– Implement the IATF 16949 automotive quality management system at production sites related to the automotive supply chain For more information on the certification status of each operational location, please visit our official website

Metrics and Targets

Key Performance Indicators for Quality Management System

Customer-Oriented Core Processes

- Customer Relationship Management

- New Product Development Management

- Production Management

- Supplier Relationship Management

- Logistics Management

- Technical Marketing and Services

Support Process

- Human Resource Management

- Infrastructure Management

- Internal Audit Management

- Instrument and Calibration Management

Business-Oriented Process

• Continuous Improvement Management

International Certification for Quality Management

- All company branches and facilities have obtained ISO 9001 certification.

- All company branches and facilities have obtained ISO 9001 certification.

International Quality Management Certification | International Quality Management Certification | ISO 9001 | IATF 16949 | IATF 16949 |

Scope of Certification | Scope of Certification | Color Chemicals Specialty Chemicals Electronic Chemicals Toner and Printing Consumables | Light Stabilizers UV Absorbers Polymer Material Additives | Photoresists |

Taiwan | Headquarters | ✓ | ✓ | ✓ |

Plant I | ✓ | |||

Plant II | ✓ | |||

Plant III | ✓ | ✓ | ||

Plant IV | ✓ | |||

Electronic Chemical Factory | ✓ | ✓ | ||

Trend Tone Imaging | ✓ | |||

China | Ethical Shanghai / Everlight Shanghai | ✓ | ✓ | |

Everlight Suzhou | ✓ | |||

Ethical Guangzhou | ✓ | ✓ | ||

Everlight Hong Kong | ✓ | |||

Europe and Americas | Everlight USA | ✓ | ✓ | |

Everlight Europe (Netherlands) | ✓ | ✓ |

Explanation for Quality Management Incident in 2022

1.Cause of Recall:

The long-term stability testing at the 36th month of Bimatoprost (E0309A02), the active pharmaceutical ingredient produced by our company for the treatment of glaucoma, showed a result of 0.16% in impurity testing (15-keto derivative), exceeding the product specification limit (15-keto derivative ≤0.15%). We immediately initiated the product recall process, notified customers, and informed the competent authority, Taiwan Food and Drug Administration (TFDA).

(1) The entire batch of products in question was sold to customers in Egypt, who confirmed that the batch of Bimatoprost (E0309A02) was completely used up in 2019, and thus the recall quantity was zero.

(2) The long-term stability testing at the 36th month was conducted in June 2022, which was beyond the expiration date of related preparation products (which was June 2022 as well). It was estimated that there should no longer be preparation products containing the batch of Bimatoprost on the market, and consequently no impact or loss to customers or consumers was incurred.

The Company has thoroughly reviewed the effectiveness of control measures for trace residues in the manufacturing process. We also used the extrapolation method to estimate the margin of error in the long-term stability testing results to prevent similar incidents from occurring again. So far, there have been no similar quality incidents with Bimatoprost (E030) or other API products.