Sustainable Products

1.Commitment to Manufacturing Sustainable Products and Implementing Chemical Safety Management to Drive Resource Efficiency and Low Carbon Transition

In 2021, Everlight Chemical established the Sustainable Product Team to define the criteria of sustainable products, evaluate existing products and manage the Company’s sustainable products.

2.Developing Green/Sustainable Products

Guided by green chemistry principles, Everlight Chemical is committed to developing and producing safer chemicals and environmentally-friendly products to mitigate the environmental impact of hazardous substances as much as possible. In 2021, Everlight Chemical established the Sustainable Product Team, which is responsible for defining and managing the Company’s sustainable products. We seek to produce products that meet our criteria for sustainable products:

- Water Conservation

- Energy Conservation (Reduced Carbon/Greenhouse Gas Emissions)

- Reduced Chemicals Requirement

- Reduced Use of VOCs (Volatile Organic Compounds)

- Reduced Environmentally Hazardous Substances

- Extended Product Life

- Use of Bio-Based Materials

3.Safe and Compliant Chemical Products ➝ Eco-Friendly Products ➝ Sustainable Products

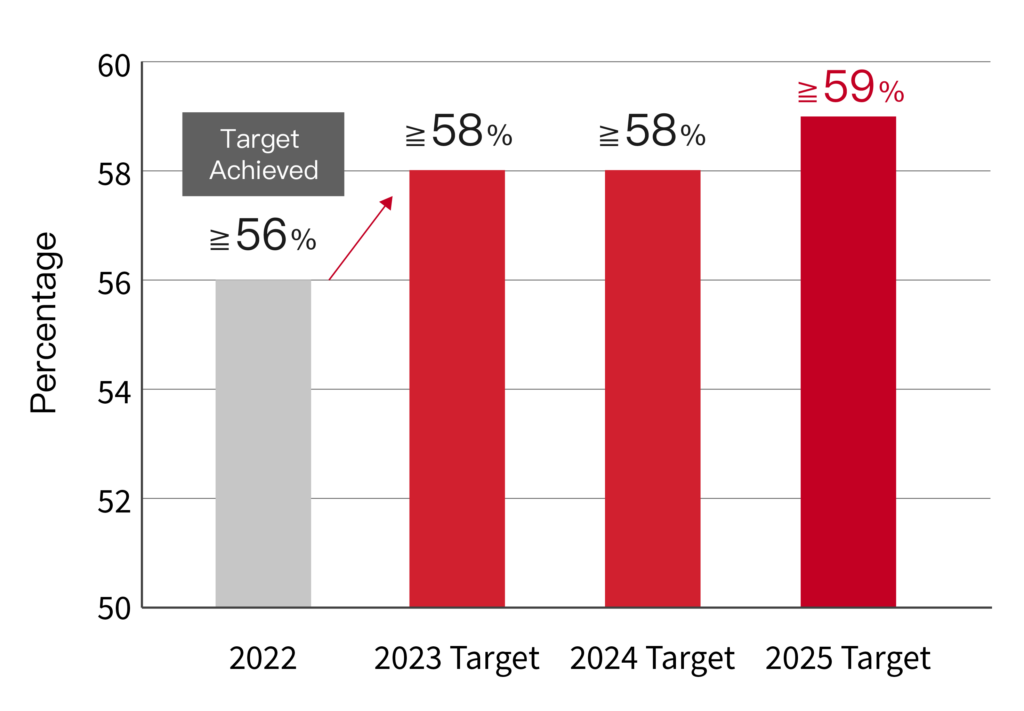

Based on our criteria for sustainable products, we calculated the share of revenue generated by sustainable products, which was 53.6% and 54.7% in 2020 and 2021 respectively. The percentage of revenue from sustainable products further increased to 56% in 2022. Looking ahead, we aim to bring the percentage up to 58% in 2023.

4.Share of Revenue from Sustainable Products: Past Performance & Future Targets

Share of Revenue from Sustainable Products: Performance & Targets

5.Key Performance Indicators

2022 Target | 2022 Actual | 2023 Target | 2024 Target | 2025 Target | ||||||||||

Group Total Revenue | UPE Product Revenue | As % of Total Revenue | Group Total Revenue | UPE Product Revenue | As % of Total Revenue | Group Total Revenue | UPE Product Revenue | As % of Total Revenue | Group Total Revenue | UPE Product Revenue | As % of Total Revenue | Group Total Revenue | UPE Product Revenue | As % of Total Revenue |

10,302 | 5,774 | 56% | 8,805 | 4,971 | 56% | 9,450 | 5,455 | 58% | 12,479 | 7,251 | 58% | 13,640 | 8,060 | 59% |

Note: UPE refers to use-phase efficiency.

6.Development of Sustainable Products in 2022

Everlight Chemical R&D Division

As part of the Evereco® PUR adhesive series that integrates ESG concepts, we continue to develop reactive PUR adhesives utilizing existing organic synthesis technology and structural analysis instruments. We have applied for relevant process patents and continued to optimize the product portfolio and clientele. We have also adopted the use of bio-based raw materials in some of the Evereco® PUR adhesives, where we employed high-adhesion PU structural design to overcome the performance limitations of bio-based materials, resulting in performance comparable to petroleum-based PUR. In 2022, we have completed the development of Evereco® PUR-2504B, which has passed adhesion performance verification by brand owners as well as ASTM-D6866 verification for bio-based content. Patent applications have also been filed.

Color Chemicals R&D Division

The Everjet® inks are designed with a focus on low volatile organic compound (VOC) content (<30%), and new products will aim for being VOC-free. Meanwhile, Everlight Chemical also actively supports ink manufacturers in producing environmentally-friendly ink products that contain low VOCs.

Specialty Chemicals R&D Division

Our reactive dyes used in medical supplies are FDA-certified. These dyes use non-toxic solvents, and the reaction relies on atmospheric air as the oxidizing agent, which helps reduce VOCs and environmentally harmful substances. This series of products can absorb visible light ranging from 450~750 nm. With anthraquinones as the main component, the products have reactive functional groups for methyl acrylate monomers and thus do not release harmful substances when applied to contact lenses.

Specialty Chemicals Technical Division

Eversorb MPP400®, one of our sustainable product offerings, is in the form of weatherable masterbatches. Thanks to its granular appearance, dust contamination is not a concern when using the product. It is also easy to mix and process, which helps extend the lifespan of customers’ products.

Electronic Chemicals R&D Division

(1)The EverSP® 100 photoresist stripers do not contain SVHC substances.

(2) The EverPI® P09 photosensitive polyimides (PSPI) employ low-temperature production processes, which enables energy conservation.

(3) The ECA 150 chemically amplified photoresists involve low exposure energy, which enables energy saving.

(2) The EverPI® P09 photosensitive polyimides (PSPI) employ low-temperature production processes, which enables energy conservation.

(3) The ECA 150 chemically amplified photoresists involve low exposure energy, which enables energy saving.

7.2022 R&D Success Highlights

Everlight Chemical R&D Division

Evereco® PUR-2504B is a new generation PUR adhesive that contains bio-based components.

Color Chemicals R&D Division

The digital textile printing (DTP) inkjet product EVERJET® RT-R603 series meets the requirements of GB 38507 in China, reducing the risk of operators’ exposure to high-VOC environment and environmental hazards.

Specialty Chemicals R&D Division

The reactive dyes for medical supplies can be used in reactive dyes for contact lenses, enhancing the visibility of transparent contact lenses for easy locating. The dyes can also be used for cosmetic contact lenses and can polymerize with ophthalmic monomers without releasing substances that pose health concerns.

Electronic Chemicals R&D Division

The division has developed eco-friendly photoresist strippers EverSP® 100, which is now supplied to the optoelectronics industry. NMP (N-Methyl-2-pyrrolidone) is widely used as a photoresist remover in the optoelectronics industry. In 2011, the European Union declared NMP as a substance of very high concern (SVHC). Everlight Chemical has developed photoresist removers that do not contain NMP or TMAH (Tetramethylammonium Hydroxide) for a greener, safer and more efficient removal process.

Trend Tone Imaging

The company’s new toner product T143-1 uses redesigned formulation, which expands its use into five additional series of printing equipment, improves the issue of decreased darkness in continuous printing of existing products (darkness degradation reduced from 30% to 9%), and replaces skin-sensitive materials.

8.Future Goals and Commitments

Everlight Chemical will continue to strengthen its actions in chemical safety management, hazardous chemical management, green procurement and green supply chain.

Our Commitments:

(1) Ensure all chemicals used in products for the textile, leather and footwear industry are 100% compliant to the ZDHC Manufacturing Restricted Substances List (ZDHC MRSL)

(2) Ensure that chemicals used in other industry verticals continue to comply with international standards (e.g., REACH SVHC and the RoHS Directive)

(3) Enhance safety awareness regarding proper chemical handling among our supply chain partners

(4) Provide sustainable products for customers, contributing to the shared efforts in advancing environmental sustainability

(5) Actively develop products with greater use-phase efficiency (UPE) to achieve win-win success for ourselves and our customers

(1) Ensure all chemicals used in products for the textile, leather and footwear industry are 100% compliant to the ZDHC Manufacturing Restricted Substances List (ZDHC MRSL)

(2) Ensure that chemicals used in other industry verticals continue to comply with international standards (e.g., REACH SVHC and the RoHS Directive)

(3) Enhance safety awareness regarding proper chemical handling among our supply chain partners

(4) Provide sustainable products for customers, contributing to the shared efforts in advancing environmental sustainability

(5) Actively develop products with greater use-phase efficiency (UPE) to achieve win-win success for ourselves and our customers